Are you planning to start your clothing line but feeling overwhelmed by the technical jargon involved in the apparel industry? Do not worry, we are here to help you decode the confusing world of grade rules in apparel manufacturing. Grading is the process of creating a range of sizes for a single apparel style, but it is not just about randomly making a pattern bigger or smaller. Grade rules are the key to producing a garment that fits proportionally across all sizes. In this post, we will cover what grade rules are, their importance in the manufacturing process, and how they can help you create a successful clothing line. So, sit tight and get ready to decode the mystery of grading in the apparel industry.

Importance of understanding grading in apparel manufacturing

Understanding grading in apparel manufacturing is paramount to delivering quality, stylish garments. Grading ensures a pattern is adjusted to fit different sizes proportionally while maintaining the same shape and fit of the original garment. The grade rules enable the manufacturer to systematically increase or decrease the middle-sized pattern based on the desired size, meaning the garment looks uniform across sizes. Without proper grading, garments may be ill-fitting and could lead to numerous returns, thus destroying the reputation of a fashion brand. Therefore, fashion designers and entrepreneurs in the apparel industry need to comprehend the basics of grading and the difference between grading and altering patterns. They must also understand grading specifications and grade rule libraries to ensure they get the best possible outcome in mass production. Understanding the factors to consider when creating grading rules and sample size measurements will help the designer produce a consistent visual across sizes and meet customer expectations.

Grading vs. Altering Patterns

Explanation of grading a pattern

Grading a pattern is the process of creating additional sizes from a sample size. Typically, a middle-sized pattern is used as the base, and it is graded up or down for larger and smaller sizes. This is done using a size specification sheet, which determines how much to increase or decrease each measurement point to maintain the same fit and shape of the garment. The main purpose of grading a pattern is to proportionally increase or decrease the size of a pattern while maintaining the same style. There are various methods to grade patterns, including the cut and spread method, pattern shifting, and computerized grading. However, grade rules are the most critical part of pattern grading. These rules determine how much each point of measurement is to be increased or decreased to create a well-fitting garment. Grade rule libraries are collections of these rules, and grading specifications outline the measurements needed to adjust the pattern for each size. By understanding the basics of grading a pattern, designers and entrepreneurs can ensure that their clothing lines have a consistent fit across sizes.

Differences between grading and altering patterns

Understanding the differences between grading and altering patterns in apparel manufacturing is important. Grading is the process of creating a full-size range for a single style while maintaining the same fit and proportion in each new size. Altering a pattern, on the other hand, is when only certain parts of the pattern are changed to create a new size for a specific person. Grading every measurement point follows a strict formula, while an altered pattern may only adjust the bust or hips, for example. Grade rules determine how much each point of measurement is made larger or smaller to fit a wide range of sizes while grading specifications indicate how much each size should change by becoming larger or shrinking.

Methods of Pattern Grading

Cut and spread

Cut and spread pattern making is a technique used to create custom patterns for clothing or other items. It involves manipulating a basic pattern to fit specific measurements or designs. To begin the process, a basic pattern is selected for the garment in question. This will serve as the foundation for the custom pattern. The pattern is then traced onto paper so that it can be cut and manipulated. Next, the pattern is cut along specific lines and then spread apart by a specific measurement. For example, if the pattern needs to be enlarged by two inches, it will be spread apart by two inches at specific points on the pattern. Once the pattern has been spread apart, the spaces in between are filled with tissue paper, and the pattern’s edges are redrawn to create the new, larger pattern.

This process can also be used to create patterns that are smaller than the original pattern. In this case, the pattern is cut along specific lines and then overlapped by a specific measurement. For example, if the pattern needs to be reduced by two inches, it will be overlapped by two inches at specific points on the pattern. Once the pattern has been overlapped, the extra material is cut off and the edges of the pattern are redrawn to create the new, smaller pattern.

In recent years, computerized grading has become a more modern and efficient pattern-making method, saving designers time and reducing the likelihood of human error.

Pattern shifting

Pattern shifting is a well-known process in pattern grading that involves increasing or decreasing the overall dimensions of a pattern. Fashion designers commonly use this process to achieve different sizes of patterns for various purposes. To increase the pattern size, designers transfer the original pattern onto another sheet of paper and move it a certain measured distance up, down, left, or right using a special ruler designed for this purpose. Conversely, to decrease the pattern size, designers have to trim the edges of the pattern to the desired dimensions. Pattern shifting is an inexpensive and simple method that requires only a pencil, ruler, scissors, and measuring tape. The results are usually consistent with the previously used cut and spread method, although can result in much more human-error.

Computerized grading

Computerized grading has revolutionized the apparel industry by allowing for faster and more precise grading. This process digitizes the cut and spread or pattern shift methods and uses a computer to handle the grading based on the set grade rules and specifications. Not only is it the fastest method, but it also reduces the risk of human error. By entering the grade rules into the computer system, it can automatically create the needed sizes for a pattern. This technology is especially useful for high-volume production, as it speeds up the grading process and reduces the workload for pattern-makers. However, it’s important to note that computerized grading is not immune to errors, and it still requires supervision and revision when necessary. At Top Notch, we specialize in computerized grading to provide the highest possible precision for grading paper patterns. Designers and entrepreneurs in the apparel industry should consider integrating computerized grading into their manufacturing process to have a more consistent fit and mainstream their production processes.

Grade Rules and Grade Rule Libraries

Definition of grade rules

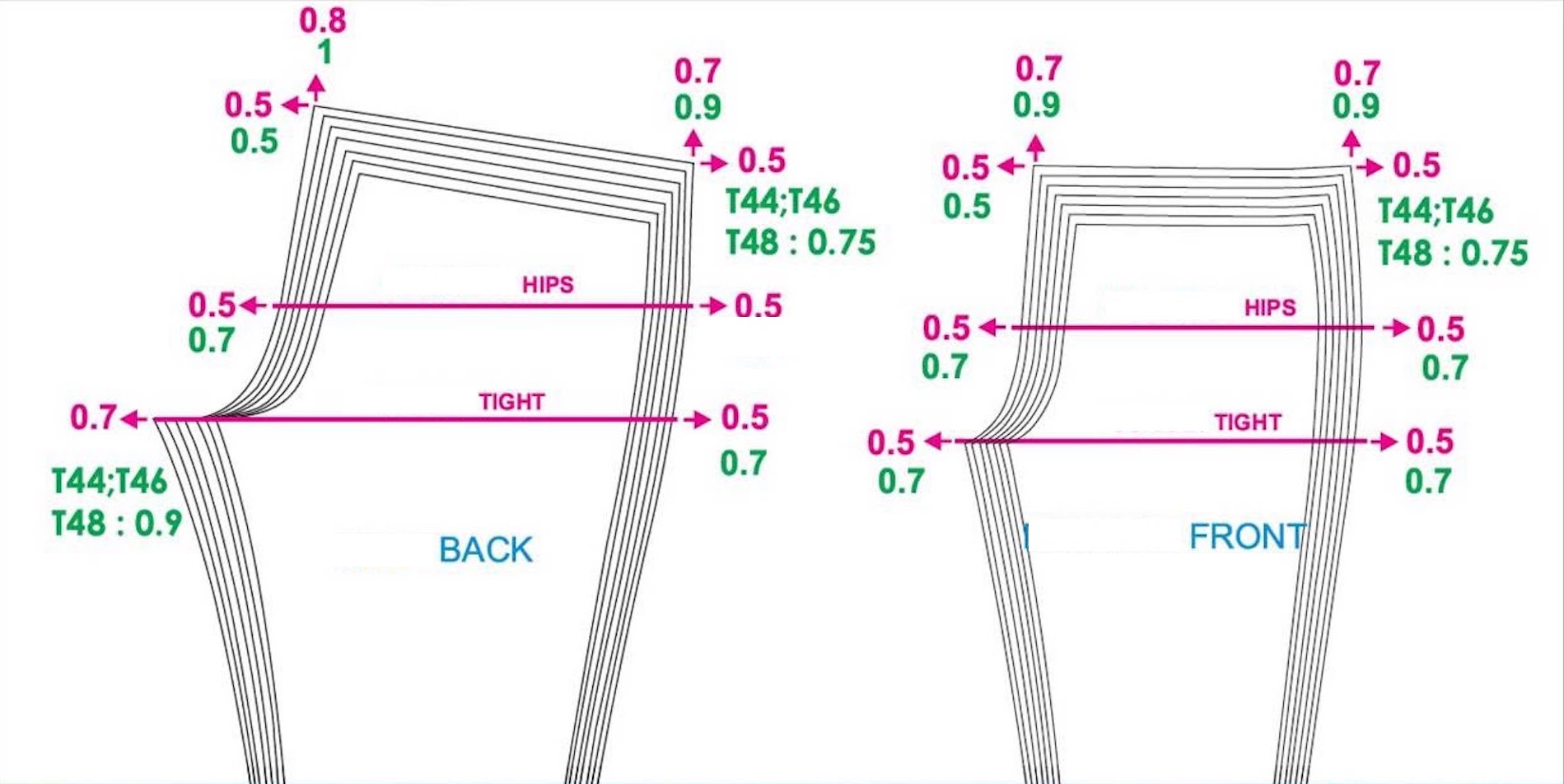

Grade rules dictate the amount of change between sizes for each measurement point on a pattern when grading a style for a range of sizes. They ensure that the garment maintains its shape and fits well in each size. The grade rules usually go up to 2 inches from size 18 with a 1/4″ length from size to size. Having a thorough understanding of grade rules is crucial for designers and entrepreneurs in the apparel industry to create successful collections that fit perfectly. A grade rule library is a collection of grade rules used to grade a pattern according to the desired size specifications. These libraries vary depending on the design features, fabric properties, and the type of grade needed. The grading specifications or grading specs are the measurements that indicate how much each size should change to become larger or smaller. They essentially provide the factory with the same information as the grade rules, delivered in a different format.

Grade rule libraries and their importance

Grade rule libraries are a collection of grade rules used to grade a pattern according to the desired size specifications. These libraries vary according to design features, fabric properties, and the type of grade. It is important to have different libraries for different types of garments, such as knit and woven tops or tops graded SML and numbered sizes. Designers don’t necessarily have to create grade rule libraries themselves, but they should know how they work and their importance in the grading process. It’s crucial to comprehend the distinction between grade rules and grading specifications. The former determines the degree of enlargement or reduction for each measurement point, while the latter indicates the extent to which each size should expand or contract. Using a bespoke grading rule system can help maximize exposure across the sizing spectrum and align the brand with the sizes of its competitors. In big-volume production, patterns are going digital, and all you need to do is enter the specified grade rules and let the computer calculate the needed sizes for your pattern.

Grading Specifications (Grade Specs)

Explanation of grading specifications

Grading specifications are large part to the success of apparel manufacturers and designers, as they indicate how much each size should grow or shrink. These measurements are essential in helping manufacturers create a wide range of sizes while maintaining the original design’s shape and fit. However, grading specs can be complicated. If you’re going for mass production, technology has eliminated the need for graded specifications, except when working with small factories. Nowadays, all you need to do is input the grade rules, and a computer does the rest. On the other hand, if you’re producing smaller volumes of custom-made clothing, creating your grading rules system is the way to go. Your grading rule will depend heavily on the kind of clothing you want to produce. For sportswear, you will need to include allowances for ease of movement, while a boxy garment will need extra room to provide an oversize fit.

Factors to consider when creating grading rules

When creating grading rules, there are several factors you need to consider to ensure that the sizing of your apparel is consistent across all sizes. Typically, grade rules will go up by 1 inch from 0-10, 1.5 inches from 12-16, and 2 inches up from 18 with a 0.25-inch length from size to size. For instance, a size 4 pattern would only be graded down 1 inch (0.5 inches in the front and 0.5 inches in the back) to create a size 2. One major factor to consider is the type of garment you’re creating. The style of your garment will determine the amount of ease and allowance you’ll need to include in your grading rules. Another key factor is the demographics of your target market. Understanding your customers’ age range and body types can help you create the proper sizing. It would help to consider the brand’s desired position in the market. How do you want your brand to be perceived among competitors?

Additionally, you need to factor in the fit preferences of your customers. Some people prefer loose-fitting clothes, while others like them more tailored. Lastly, having accurate sample size measurements and updating them frequently is important. By considering these factors, you can create effective grading rules that cater to your target market and ensure consistent sizing across all apparel sizes.

Final Thoughts

In conclusion, understanding grading rules in apparel manufacturing is critical for designers and entrepreneurs aiming to build a successful brand in the industry. Grading is the process of developing patterns in multiple sizes, and it’s essential to know the distinctions between grading and altering patterns. Cut and spread, pattern shifting, and computerized grading are all effective grading methods, but we recommend computerized. Designers and entrepreneurs must know what grade rules are, what grade rule libraries are, and how important they are for creating efficient grading specifications. Additionally, factors like sample size measurements need consideration when creating grading rules. By using the right grading rules, designers can save time, minimize errors and costs, and increase production efficiency. This knowledge, coupled with creativity, innovative ideas and new inventions, and awareness of industry best practices, can help designers thrive in the highly competitive apparel industry. Still not sure how it all works? Top Notch Pattern is well-versed in custom grade rules and industry standards, and we guide our customers through what their grade rules should be to match the fit they’re trying to achieve. We’ve worked with over 1000+ different brands over 30 years, and we’ve seen the different sizing options from every corner of the fashion industry.